|

A healthy starter motor is a great asset on overland journeys – specially when traveling with a heavy truck like the Mercedes Benz 1719AK expedition truck. Here’s a bit about the symptoms of a dying starter motor. Also a bush travelers trick to get a heavy diesel engine running.

In this article;

Weak engine starting

The instant thought when hearing the slow grind of a starter motor is to charge or replace batteries. In most cases weak batteries are the main cause of a hesitant engine start.

But in this case the batteries are new and fully charged. Read about how several other parts in the electrical starting system caused a weak start of a 10 liter OM401 diesel engine.

The starter motor for the OM401 engine was the ELMOT R23.08 starter motor - a BOSCH starter motor imitation.

|

| Bosch imitation start motor- ELMOT R23.08 4.5Kw 24 volt - with rear casing removed |

|

|

| ELMOT brand stamp and a view at the solonoid relay |

|

With new batteries the weak start remained – meaning starting current was dissipated elsewhere in the electric starter motor circuit.

Battery safety switch and ground cables

A deeper dig into the electrical starter system revealed a circuit breaker close to breaking down – the battery safety switch. The backside showed signs of heating causing the plastic housing to crack when one of the connector bolts was turned. With thick sturdy battery cables, the contacts within the cracked safety switch housing could already be misaligned causing bad contact.

|

| Battery safety switch - contacts are pressed into a plastic housing |

Next 2 ground cable strips – connecting battery minus to the chassis – where heavily corroded. Ground cable corrosion causes resistant and a voltage drop leading to less power to end up at the starter motor.

|

| Corroded ground cable from starter motor to chassis. |

With these 2 parts replaced – starting the engine sounded a bit better. Though compared to starting a similar OM401 is was still too weak, specially at sub-zero temperatures.

On top of that, the starter motor sometimes engaged just a fraction of a second later after the start button was pressed. This revealed the hard click of the solenoid relay – a sound which is normally hidden in the roar of an immediate engine start.

Worn ELMOT starter motor – a BOSCH imitation

The OM401 engine was already equipped with a replacement starter motor about 10 years ago. It’s a ELMOT R23.08 electrical starter rated 5.4 Kw at 24 volts produced by the Indian company Elmot Alternators Pvt Ltd in New Dehli. The original starter motor is a BOSCH (A 004 151 60 01) or DELCO (A 005 151 27 01).

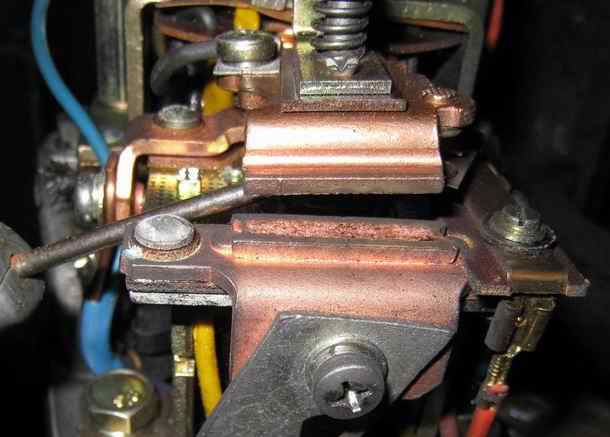

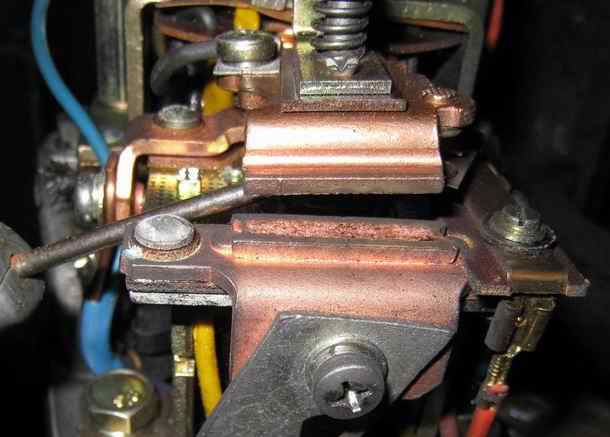

Opening the rear end of the starter motor revealed the solenoid starter relay. At first glance all looked ok and relatively clean. Though at closer inspection the starter motor commutator showed signs of severe wear – parts of a copper segments was burned.

|

| Burned out copper segment of the commutator in starter motor |

Copper commutator segment and starter brush residue was found in the rear end casing.

|

| Burned brush and commutator (similar to a slip ring) particles in starter motor |

The main relay contacts also showed signs of contact wear.

|

| Worn solenoid relay contacts |

The rest of the smaller relay contacts seems ok.

All these findings together explained the symptoms of weak and sometimes delayed starting. Though the ELMOT starter motor never failed to start the engine – but it was time to replace it with a refurbished original BOSCH starter motor.

Buying a BOSCH starter motor

A round up of starter motor prices in Europe in early 2011 showed considerable price differences among suppliers. On top of that - BOSCH imitation starter motors from china have flooded the market averaging at a price of € 200,-

Refurbished DELCO and BOSCH starter motors were sold for € 350 - € 400 while a new original starter motor hits the wallet for about € 550,-

|

| Original refurbished Bosch Startermotor 24V 5.4kW partnumber A0041516001 |

In this case a refurbished BOSCH starter motor was bought for € 345,- with the ELMOT as trade starter motor.

After installation starting the 10 liter engine was instant, strong in sound and without delay.

Occasional failed engine start - solenoid click

After new BOSCH batteries and starter motor one problem remained. Occasionally an attempt to start the engine resulted in hearing just the click of the starter motor solenoid relay. Another crank attempt always started the engine immediately. It never resulted in not being able to start the engine. On average the problem occurred every 20 to 40 starts.

After a long search the problem was found – it’s a tooth against tooth problem because of 3 worn teeth on the fly wheel. A single starter pinion tooth hits the flywheel tooth straight on and stays there.

|

|

| Damaged flywheel teeth by startermotor pinion |

|

Because the engine always stops in several fixed positions, the flywheel is always engaged by the pinion at the same spots. So it’s pure chance the exact 3 worn flywheel teeth are positioned just at the starter motor causing a failed start.

In this case the problem is eased by putting a little thick grease on the damaged teeth improving the slide action between pinion and flywheel teeth.

BOSCH Starter batteries and Mastervolt charger

Starter batteries were replaced with BOSCH T5 HDE 225 Ah "Heavy Duty Extra"commercial truck batteries. The heaviest in their league capable of delivering a whopping 1150 Amps at cold crank start.

|

|

| BOSCH T5 starter battery charged by a Mastervolt 35Amp charger |

|

The BOSCH T5 batteries are charged with a dual output Mastervolt Combi Mass 35 Amp@ 24 volt battery charger – charging starter batteries and living / household batteries.

Alternative engine starting – cranking

It’s still possible to start a combustion engine when the starter motor fails to do so. The trick is based on the axle differential principle. This video from India explains it all:

Starter motor technical information

|

WIKI starter motor article |